compressed air leak test procedure|leak testing methods pdf : advice Get expert insights on air leak detection methods and repair techniques. Uncover the hidden costs of compressed air leaks, from higher energy bills to shorter equipment lifespan. Searching for the old Friv? Here it is! It’s the Friv menu from back in the Flash days – the one you used to use when you were a kid back at school.

{plog:ftitle_list}

Resultado da xHamsterLive is 100% free and access is instant. Browse through hundreds of models from Women, Men, Couples, and Transsexuals performing live sex .

Wondering how to stop compressed air leaks? Discover air leak detection methods and repair techniques to optimize system performance and reduce maintenance costs.Get expert insights on air leak detection methods and repair techniques. Uncover the hidden costs of compressed air leaks, from higher energy bills to shorter equipment lifespan.By following the below formula, we can determine the right air leak test method and leak tester for your application. innomatec uses a lettered system to indicate different leak testers used . A compressed-air system analysis consists of a complete review of the compressed-air system from the air intake to the end users, plus a .

A compressed air system analysis consists of a complete review of the compressed air system from the air intake to the end users, plus a compressed air leak detection and correction . Compressed Air Leak Detection 101. Read the following resource article to learn more about the leak detection process, why it is important, and how Zorn Compressor & .To prevent energy loss and ensure optimal performance of your air compressor system, Atlas Copco brings you a complete compressed air leak check program, providing a leakage .Air Leak Test of your installation verifies and measures the reason for compressed air wastage, which will help you arrest the expensive leaks. That said, compressed air leak testing is also a clean way to check if your .

An initial pneumatic leak test may be conducted utilizing compressed air or inert gas if the pressure is limited to 7.25psi. An initial service test for ASME Category D fluids (nontoxic, .> Compressed air supply > Tools > Stability of sample Fig. 5 — Identify which air leak test method is best suited to your application based on required leak rate, maximum test pressure, and maximum temperature differences likely to occur during test. Air leak testing Leakage rate Maximum test pressure Maximum Differences Possible method A compressed-air system analysis consists of a complete review of the compressed-air system from the air intake to the end users, plus a compressed-air leak detection and correction program. To achieve success .Preliminary pneumatic test: a preliminary test using air at no more than 170 kPa (25 psi) gage pressure may be made prior to hydrostatic or pneumatic testing to locate major leaks. Examination for leaks: a leak test shall be maintained for .

leakage testing methods

1.2 Compressed-Air Leak Survey and Repairs Leaks are a significant cause of wasted energy in a compressed-air system and can develop in many parts of a compressed air system. The most common problem areas are couplings; hoses; tubes; fittings pipe joints quick disconnects; filters, regulators, and lubricators; condensate traps;

Air Leak Test of your installation verifies and measures the reason for compressed air wastage, which will help you arrest the expensive leaks. That said, compressed air leak testing is also a clean way to check if your compressed air system meets leak-tight specifications.B31.1 – 2012 Power Piping covers the testing procedures for hydrostatic and pneumatic tests in only two pages. The emphasis is on the process of pressure testing, rather than . Water can’t be compressed like the air or gas used by itself for pneumatic testing, so considerably less stored energy is generated. While there are still hazards

Understanding how to test for leaks in the air compressor valve is essential for ensuring optimal performance and cost-effective operation. By implementing proper testing techniques, businesses and individuals can proactively identify and repair leaks, ultimately saving time, energy, and money. . Pressure Testing Procedures for Air Compressor .4 Pressure testing to find leaks Page 4 5 Leak test procedure Page 5 6 Reducing leakage and common leak points Page 6 . Commercial and industrial refrigeration and air conditioning systems leak too much refrigerant – leaks of up to 30% of the charge during a year are not uncommon. . and compressor suction. Allowed under the F Gas .Conducting an air leak test at the right time can prevent the leakage issues from affecting the final user points. To put it simply, an air leaking test is an evaluative method to scan for leakage issues and analyze pressure in your air compressor. Following are the benefits of performing an air leak test: Leak standards are quantifiedoil aerosol in compressed air. This simply alerts you if aerosol is present in your compressed air. A kit is available to order which will allow you (the customer) to take a small air sample and send it to a laboratory for air-testing. Note, this test does not include microorganisms testing. The analysis provided would cover all points in the list

leak testing methods pdf

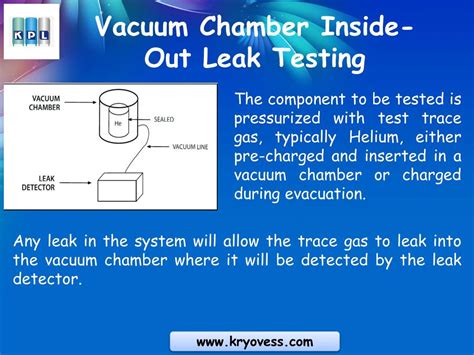

Leak Testing - TQC's beginners and fundamentals guide to helium leak testing, what is it, why use it and the benefits of helium leak testing. Please call: +44 (0)115 950 3561. . First of these is to mix the helium with another lower cost gas, either nitrogen or compressed air. This is only possible where the sensitivity of the test is not .

P t =1.5*P d *(S t /S d) . Here, P t =the minimum test gauge pressure P d =internal design gauge pressure S t =allowable stress value at the test temperature S d =allowable stress value at design temperature. The maximum allowable value of S t /S d is 6.5. Note that, ASME B31.3 provides a provision to reduce the hydrostatic test pressure in piping under certain . A mechanic performing an engine cylinder leak down test – jerrypetrillo.com Step 1: Get the tools you need . We are gonna need some stuff to get this test done. A socket and ratchet to rotate the engine by hand; A decent engine cylinder leak down tester; The correct hose for the tester; A compressed air source (an air compressor that can .

custom money tree plant moisture meter

ASME B31.3 outlines specific hydrostatic (water) and pneumatic (air) testing procedures. Hydrostatic testing involves filling the piping system with water and applying pressure, while pneumatic testing uses compressed air or gas. The standard provides detailed guidelines on pressure levels, duration, and procedures for conducting these tests. This type of testing is typically employed for systems that handle gases or compressed air. Pneumatic testing helps assess the system’s ability to withstand pressure, detect leaks, and ensure overall reliability and .

Nitrogen Leak Test This test is performed to ensure that there are no leaks in the piping, compressor, or other pressure containing parts of the package. 1. All openings in the completed compressor package are plugged and the unit is pressurized with nitrogen to 350 psig. On water-cooled units the water jackets are tested to 100 psig. 2. In this piece, we will further explore how each type of impurity can occur and will discuss how to test compressed air/gas quality. Compressed Air Testing Methods. Each of the types of potential air quality issues has different .There are 2 basic techniques; high vacuum testing which allows leak test thresholds to be set down as low as 1x10 -12 mbar.l.sec -1 , or sniffing which is generally used for helium leaks down to 1x10 -6 mbar.l.sec 1 .

A cylinder leak down test, can tell you if the loss of compression is from, worn rings, burned or stuck open valves or a leaking head gasket. . (ECM) About Air Flow; Testing Procedures And Fixes – To Keep You On The Road. Cooling Heating System, Also Shares, Many Of The Same Parts; Electrical System Testing, Sensors, Relays, Ignition . In Part 2 of The Beginners Guide to Leak Testing we delve into the fundamental techniques of leak testing using air as the testing medium. English English 简体中文 . While the straightforward method involves dunk testing, where compressed air is pushed into the test piece underwater, the approach has notable limitations. Commonly . The temperature (T Leak) and pressure (p Leak) of the air at the exhaust of the leak are needed to calculate the air density under ideal gas conditions (Eq. 2 ). As long as the shape of the leakage differs from a laval nozzle, the so called critical pressure will adjust at the exhaust, it is a direct result of reaching the sonic flow speed.

leak test results

According to the Compressed Air and Gas Institute (CAGI) and the International Organization for Standardization (ISO), the three major contaminants in compressed air are solid particles, water, and oil. CAGI promotes proper use of air compressors with various educational tools, while ISO 8573 is directed at the very specific areas of compressed air purity and test .For the leak tests specified in Table 1, tank air tests, compressed air fillet weld tests, vacuum box tests in accordance with 4.4.4 through 4.4.6, or their combination, will be acceptable. Hydrostatic or hydropneumatic tests may also be accepted as leak tests provided that 4.5,

Importance of Leak Detections. Compressed air leaks are an extremely costly issue when it comes to compressed air. Leaks provide a significant source of wasted energy, wasting as much as 20%-30% of your compressor’s output! Aside from wasted energy, output, and cost, leaks can also create other problems within your system, including but not limited to:6.5.1 Where a leak test is specified in Table 3.6.1 Testing requirements, unless specified otherwise, a tank air test, compressed air fillet weld test, or vacuum box test is to be carried out in accordance with the applicable requirements of Pt 4, Ch 3, 6.6 Definitions and details of tests 6.6.4 to Pt 4, Ch 3, 6.6 Definitions and details of tests 6.6.6.Plus, we use standard testing processes and compare data across our entire network — leading to greater efficiency, consistency, and value for our customers. 1. Identify and tag leaks . Total Operating Compressor hp Wasted Power $ (Air Leaks) Air Leaks at 6.5¢ / kWh, 10 – 20% of Capacity Air Leaks at 13¢ / kWh, 10 – 20% of CapacityCompressed Air System Performance. Acknowledgments . 2-Potentially Inappropriate Uses of Compressed Air 23 3-Compressed Air System Leaks 27 4-Pressure Drop and Controlling System Pressure 31 5-Compressed Air System Controls 35 6-Compressed Air Storage 41 7-Proven Opportunities at the Component Level 47

leak test output

best leak testing methods

air leak testing methods

Albinea: Previsioni Meteo di Domani mattina, pomeriggio, ser.

compressed air leak test procedure|leak testing methods pdf